OUR QUALITY CONTROL

Our products are manufactured in HACCP-certified facilities and undergo rigorous quality control at every stage. Our experienced QC team implements a comprehensive 5-point inspection system, from raw material sourcing through to container loading.

1. Input Traceability Control

Depending on the seafood type, raw materials are sourced from different locations:

- Licensed fishermen with complete documentation for wild-caught seafood

- Certified farmers for farmed seafood

We maintain a zero-tolerance policy for illegal, unreported, and unregulated (IUU) fishing activities. For farmed seafood, we prioritize suppliers holding internationally recognized certifications such as ASC, BAP, and Global GAP.

All raw materials must be fresh and transported under appropriate temperature-controlled conditions before arriving at our processing facilities.

2. Production Process Control

Our partner factories maintain complete flow charts and quality control systems. Most facilities are accredited with internationally recognized standards including ISO, BRC, and IFS certifications.

Throughout production:

- Processing temperatures and product temperatures are continuously monitored and recorded

- Our QC team conducts frequent on-line inspections

- Production samples are periodically submitted to third-party laboratories for independent testing

3. Storage Control

We maintain strict cold storage standards:

- Storage temperatures are monitored normally from -20°C to -22°C (minimum -18°C)

- Products are properly palletized with clear labeling

- Designated storage zones prevent cross-contamination and product mix-ups

4. Pre-Shipment Inspection

Once orders are complete, our QC team conducts comprehensive on-site inspections:

- Quantity count

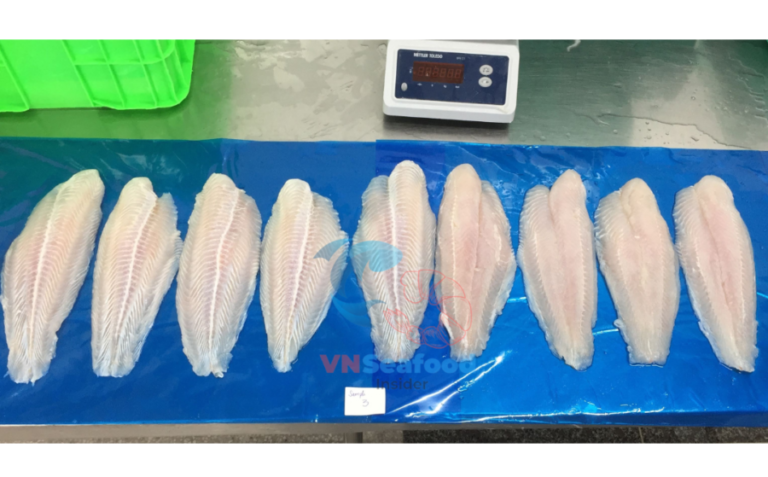

- Sensory evaluation

- Defrosting samples for quality assessment

- Cooking tests (when required)

Independent laboratory testing through SGS, Intertek, or Bureau Veritas is arranged as needed. Detailed inspection reports are provided to customers before shipment.

5. Container Loading Supervision

Our final quality checkpoint includes:

- Container temperature verification

- Photographic documentation of loading positions for each line

- Core product temperature checks (minimum -18°C)

- Container loading chart

- Complete loading reports submitted to customers