You’ve just received a shipment of Vietnamese seafood at an unbelievably low price. The excitement quickly turns to disappointment when your customers complain about mushy texture and bland taste. Sound familiar? You’ve likely encountered the common issue of oversoaked seafood products. As VNSeafoodInsider, we’ve seen this scenario play out countless times, and today we’ll share everything you need to know about navigating Vietnam’s complex seafood quality landscape.

Vietnam stands as one of the world’s leading seafood exporters, shipping billions of dollars worth of aquatic products globally each year. However, with great volume comes great responsibility – and unfortunately, not all producers maintain the same quality standards. For importers like you, understanding seafood quality control Vietnam practices isn’t just helpful; it’s absolutely crucial for protecting your business reputation and ensuring customer satisfaction.

Throughout this comprehensive guide, we’ll decode the mystery behind additive treatment practices, reveal detection methods that actually work, and equip you with the knowledge to make informed purchasing decisions. Because let’s face it – nobody wants to explain to their customers why their expensive shrimp turned into rubber during cooking.

Outline

ToggleUnderstanding Seafood Quality Control Vietnam Standards

Vietnam’s seafood industry has transformed dramatically over the past two decades, evolving from small-scale fishing operations to sophisticated aquaculture and processing facilities. This rapid growth has created a diverse ecosystem where world-class producers operate alongside facilities with questionable practices.

The Vietnamese government has established comprehensive regulations governing seafood exports, particularly through the Vietnam Administration for Food Safety (VFA) and the National Agro-Forestry-Fisheries Quality Assurance Department (NAFIQAD). These organizations oversee everything from pond-to-plate traceability to chemical residue testing. However, enforcement can vary significantly across different regions and facility sizes.

Modern Vietnamese seafood factories typically implement multi-layered quality control systems including HACCP protocols, temperature monitoring, and batch tracking systems. The better facilities invest heavily in laboratory equipment and trained personnel to ensure consistent product quality. Yet the industry’s competitive pricing pressure sometimes pushes less scrupulous operators toward cost-cutting measures that compromise product integrity.

International compliance requirements add another layer of complexity. Seafood quality control Vietnam must simultaneously meet EU regulations (which emphasize natural products with minimal processing), US standards (which allow more flexibility with additives), and Japanese requirements (which focus heavily on freshness and appearance). This creates a challenging balancing act for exporters serving multiple markets.

See more: Vietnam Seafood Export Statistics 2025

Vietnamese Seafood Quality Standards: Why Exporters Use Additive Treatment

Let’s address the elephant in the room – additive treatment isn’t inherently evil. When done properly and transparently, certain treatments serve legitimate purposes that can actually enhance product quality and safety.

Water retention treatments help maintain freshness during the long journey from Vietnamese processing facilities to your warehouse. Without proper moisture retention, seafood can develop off-flavors and unappetizing textures. The key word here is “proper” – there’s a significant difference between appropriate treatment and oversoaking.

Legitimate Reasons for Additive Treatment

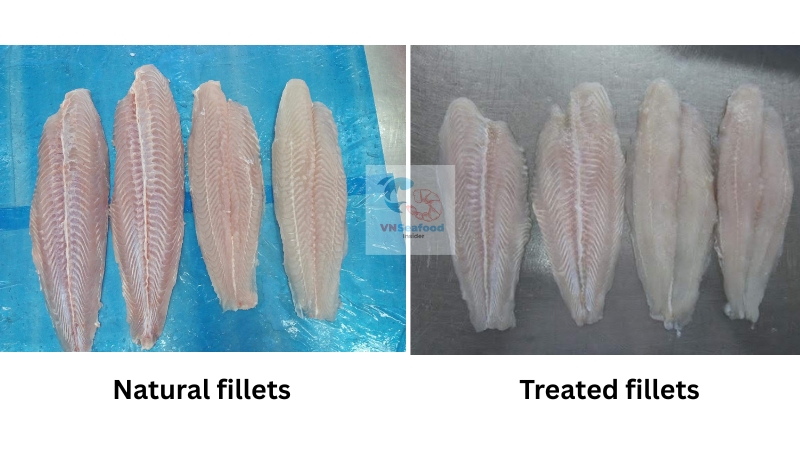

Color enhancement represents another common practice, particularly with pangasius fillets. Natural pangasius can have a slightly pinky that doesn’t appeal to Western consumers expecting pristine white fish. Light treatment can create the bright white appearance that drives sales, similar to how bread manufacturers bleach flour.

Taste enhancement caters to specific market preferences. American consumers generally prefer seafood with a slightly saltier profile, so Vietnamese exporters often add controlled amounts of salt during processing. This isn’t deception – it’s market adaptation.

The cultural divide becomes particularly apparent when comparing US versus EU market expectations. American buyers often prioritize appearance and longer shelf life, accepting reasonable levels of processing to achieve these goals. European importers, however, increasingly demand products that maintain their natural characteristics with minimal intervention.

See more: Pangasius Quality Control – How to Avoid Quality Issues When Importing Pangasius

Vietnamese Seafood Quality Standards: Which Products Are Commonly Treated

Understanding which products commonly undergo treatment helps you focus your quality control efforts where they matter most. Not all seafood receives equal treatment – certain products are simply more vulnerable to processing modifications.

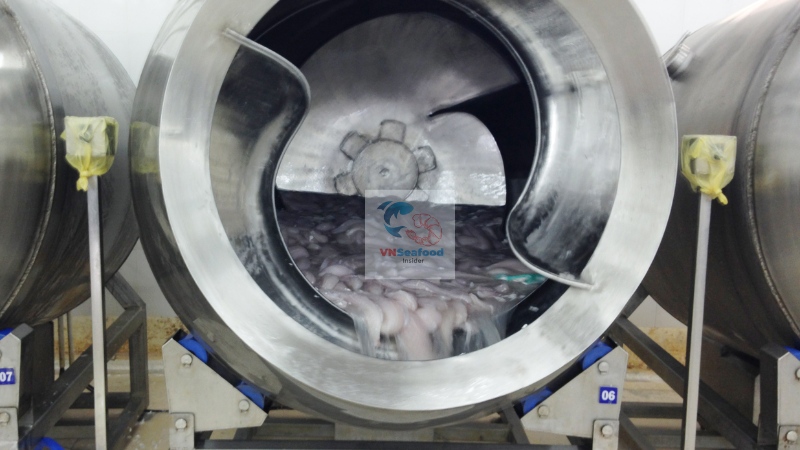

Fish fillets, particularly pangasius and tilapia, represent the highest-risk category for oversoaking. These products lack protective skin barriers and have naturally high water content, making them ideal candidates for water-retention treatments. Vietnamese processors can easily increase product weight by 30-40% through aggressive soaking practices.

Shrimp products, especially peeled varieties, face similar vulnerabilities. The removal of shells eliminates natural protection, allowing chemicals to penetrate quickly and deeply. Whole shrimp with shells intact rarely undergo significant treatment since the processing would be ineffective and economically unfeasible.

The skinless factor cannot be overstated in seafood quality control Vietnam considerations. Products with natural protective barriers (shells, skin, scales) resist treatment penetration, making oversoaking both difficult and economically unattractive. This explains why whole fish rarely suffer from oversoaking issues compared to their filleted counterparts.

Processing methods vary significantly across different facilities and product types. High-volume processors serving price-sensitive markets may employ aggressive treatment protocols, while premium-focused facilities typically use minimal intervention approaches. Understanding these differences helps you select suppliers aligned with your quality expectations.

See more: Top 3 Of The Best Frozen Shrimp Products for Importers

Oversoaked Seafood Detection: Signs and Testing Methods

Recognition is your first line of defense against oversoaked products. Developing reliable detection skills protects your investment and prevents customer dissatisfaction. The good news? Oversoaked seafood exhibits predictable characteristics that become obvious once you know what to look for.

Sensory Detection Methods

Visual inspection reveals numerous telltale signs of oversoaking. Excessive whiteness in normally translucent products suggests chemical bleaching. Unnatural shininess or artificial-looking surfaces indicate recent treatment. Pay particular attention to color uniformity – natural seafood exhibits subtle color variations that processing tends to eliminate.

Texture assessment provides even more reliable indicators. Fresh, properly handled seafood feels firm and resilient under gentle pressure. Oversoaked products feel mushy, spongy, or artificially swollen. The flesh may appear to separate easily or have a water-logged appearance.

Laboratory Testing

Professional seafood quality control Vietnam relies heavily on moisture content analysis. Natural seafood contains predictable moisture levels – typically 78-83% for most fish species and 75-80% for shrimp. Products exceeding these ranges by significant margins likely underwent aggressive water-retention treatments.

Chemical additive detection requires more sophisticated testing but provides definitive answers about treatment history. Common additives include sodium tripolyphosphates, sodium, and various salt solutions. Laboratory analysis can identify and quantify these substances with high accuracy.

Cooking Test Indicators

The kitchen test remains one of the most practical detection methods available. Simply cooking a small sample reveals oversoaking issues that visual inspection might miss. Excessive water discharge during cooking – beyond normal moisture loss – indicates artificial water retention.

Texture changes during cooking provide additional clues. Naturally processed seafood maintains structural integrity and develops appealing textures when cooked properly. Oversoaked products become increasingly mushy and may even disintegrate during preparation.

Price Indicators and Red Flags in Seafood Quality Control Vietnam

Price analysis serves as a powerful early warning system for quality issues. While Vietnamese seafood offers excellent value compared to many alternatives, prices that seem too good to be true usually are exactly that.

Understanding the economics helps explain why oversoaking occurs. Water costs virtually nothing, while seafood commands premium prices. Adding 20% water weight to a product effectively increases revenue by the same percentage – a tempting proposition for unscrupulous suppliers.

Market price benchmarks provide reference points for evaluation. Premium pangasius fillets typically trade within specific price ranges based on global market conditions. Quotations significantly below these benchmarks deserve skeptical examination and additional quality verification.

Extremely low quotations should trigger immediate red flags about seafood quality control Vietnam standards. While legitimate reasons for competitive pricing exist (seasonal abundance, direct factory relationships, bulk purchasing), dramatic price reductions often correlate with compromised quality practices.

See more: Material price indicator for main Vietnam Seafood.

Best Practices for Seafood Quality Control Vietnam

Implementing systematic quality control practices protects your investment and builds long-term business success. The key lies in creating multiple verification layers that catch problems before they reach your customers.

Pre-shipment inspection protocols should include both visual assessment and lab testing when dealing with unfamiliar suppliers. Many Vietnamese exporters welcome third-party inspections and view them as opportunities to demonstrate their quality commitments.

Working with certified suppliers significantly reduces quality risks. Look for facilities with international certifications (BRC, ISO 22000, IFS) and strong reputations within the Vietnamese seafood community. These operations typically maintain consistent standards and provide reliable quality documentation.

Documentation and traceability requirements have become increasingly important in global seafood trade. Reputable Vietnamese suppliers provide comprehensive paperwork including processing records, laboratory test results, and chain-of-custody documentation. This transparency demonstrates commitment to quality and facilitates problem resolution when issues arise.

Building long-term supplier relationships creates mutual incentives for quality maintenance. Vietnamese exporters value stable, long-term partnerships and often provide preferential treatment and quality commitments to loyal customers. This relationship-based approach aligns with Vietnamese business culture and produces better outcomes than purely transactional interactions.

Third-party verification adds an essential layer of objectivity to seafood quality control Vietnam processes. Independent inspections, laboratory testing, and certification services provide unbiased assessments that protect both buyers and sellers from misunderstandings or disputes.

Ready to ensure your Vietnamese seafood meets the highest quality standards? VNSeafoodInsider offers comprehensive supplier verification and quality assessment services throughout Vietnam’s seafood industry. Our local expertise and extensive network help you identify reliable partners while avoiding costly quality issues. Contact us today for consultation and discover how proper seafood quality control Vietnam practices can transform your sourcing success.

Pingback: Phosphate Treatment in Fish Fillets: EU Standards, Moisture Limits, and Buyer Guide