If you’re a seafood buyer importing fish fillets into the European Union, you’ve probably heard the term “phosphate treatment in fish fillets” more times than you can count. Maybe you’ve even scratched your head when one Vietnamese supplier tells you their product is 86% moisture, while another confidently quotes 89%—and both claim to meet “EU treatment standards.”

Here’s the thing: phosphate treatment isn’t just a technicality. It’s a legal, commercial, and quality-control issue that can make or break your shipment at customs. At VNSeafoodInsider, we’ve seen too many well-meaning buyers get tripped up by misconceptions, incomplete spec sheets, and the assumption that there’s a single magic number everyone follows.

In this guide, we’ll walk you through everything you need to know—from what the EU treatment standard actually means, to how factories dial in their moisture content, and what you should be asking your suppliers before you sign that purchase order. Let’s dive in.

Outline

ToggleUnderstanding EU Treatment Standards for Fish Fillets

So, what exactly is the EU treatment standard?

Here’s where things get interesting—and a little messy. Many buyers assume there’s one official moisture percentage stamped by Brussels that every processor must hit. The reality? There isn’t.

The European Union sets rules around food safety, labelling, and additives—but it doesn’t dictate a single moisture target for all fish fillets. What the EU does require is transparency: if water is added during processing, or if phosphates are used, you must label it clearly.

In Vietnam’s pangasius sector, for example, you’ll find plants targeting 86% moisture, others going for 88%, and some pushing 89%—all within what they call “EU compliant.” The key difference lies in their treatment formulation, tumbling protocols, and how they interpret allowable water retention.

Bottom line for importers: Don’t assume a fixed benchmark. Always review your supplier’s spec sheet and understand their version of the EU standard. Ask questions. Get it in writing.

Phosphate vs. Non-Phosphate Treatment — What Buyers Should Know

Let’s clarify the basics. Phosphate treatment in fish fillets involves soaking or tumbling the fish in a solution containing sodium tripolyphosphate (STPP) and salt. Why? Because polyphosphates help fish muscle proteins hold onto water, improving texture, reducing drip loss, and extending shelf life.

Non-phosphate treatment, on the other hand, relies on mechanical water retention—often through extended tumbling in ice-cold water without added chemicals. It’s cleaner on the ingredient deck, but typically yields lower moisture levels and requires different labelling.

Both methods are legal in the EU, provided you follow the rules:

- If your fillet is treated with phosphates and water is added, the label must say “treated with phosphates” and “water added”.

- The added water should generally fall within 5–20% of the product weight, depending on the species and method.

- Using unapproved chemicals or misleading consumers about moisture content? That’s a one-way ticket to rejection at the port.

Understanding these distinctions helps you choose the right product for your market—and avoid nasty surprises during customs inspections.

EU Moisture Content Limits and Labelling Requirements

The EU takes moisture content seriously. Not because they’re picky (okay, maybe a little), but because they want to protect consumers from paying premium prices for frozen water.

Here’s the regulatory framework in plain English:

- Water addition is allowed, but it must be reasonable—typically 5–20% depending on the fish species and processing method.

- Labelling is mandatory: If your fish fillet contains added water or has been treated with phosphates, the packaging must state it clearly. No fine print. No clever wording.

- No sneaky additives: The EU bans any chemicals or processing aids not on their approved list. Polyphosphates are fine; mystery ingredients are not.

For you as a buyer, this means due diligence is non-negotiable. Request a Certificate of Analysis (COA) for every batch. Cross-check the label language. Make sure your supplier understands EU labelling laws as well as they understand their tumbler settings.

See more: Pangasius Export Prices Set to Rise in Q4 2025

How Vietnamese Factories Achieve Target Moisture Levels

Ever wonder how a Vietnamese pangasius plant consistently hits 88% or 89% moisture while staying (mostly) within EU guidelines? The answer lies in two things: treatment formulation and tumbling time.

Let’s start with the formula. Based on FAO guidelines and industry best practices, a typical phosphate treatment solution looks like this:

- Sodium tripolyphosphate (STPP): 3–6% of solution weight

- Salt (NaCl): 0.5–1.5%

- Solution-to-fish ratio: 5–10% of fish weight

- Solution temperature: 0–5°C (ice-cold is ideal)

- Target pH: 7.5–8.2 (this range optimizes protein water-binding)

When you combine these elements, the polyphosphate works its magic: it loosens the actomyosin complex in the fish muscle, creating space for water molecules to slip in and stay put. The result? A fillet that’s juicier, firmer, and—yes—heavier.

But here’s the catch: if the formula is too aggressive (say, 6% STPP with extended tumbling), moisture can creep toward 89%, which must be declared as “water added” under EU rules. Some buyers are fine with that; others prefer a lighter touch at 84–85% moisture to avoid the “watered down” perception.

Know your market. Know your customer. Then work backward to the right moisture target.

The Role of Tumbling Time in Phosphate Treatment in Fish Fillets

If the treatment solution is the recipe, then tumbling time is the cooking method. And just like with cooking, timing is everything.

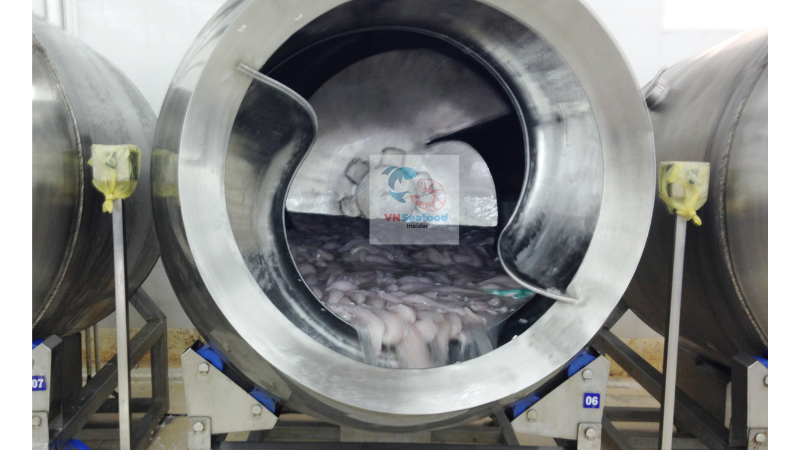

Tumbling is the process of gently rotating fish fillets in a large drum with the phosphate solution. The mechanical action helps the solution penetrate the tissue evenly, while also massaging the muscle to improve texture.

Here’s how tumbling time correlates with moisture levels in practice:

- 10–20 minutes with a diluted solution (3–4% STPP): Yields 84–85% moisture, often marketed as “standard treatment” or “light moisture retention.”

- 30–45 minutes with a moderate solution (5% STPP): Pushes moisture to 86–87%, a sweet spot for many EU buyers.

- 45–60 minutes or longer with a stronger solution (5–6% STPP): Can reach 88–89% moisture, requiring clear labelling as “treated with phosphates and water added.”

Why does this matter to you? Because tumbling time is one of the variables your supplier can control—and adjust—based on your specs. If you need a drier product, ask them to shorten the tumble. If you want maximum yield and moisture, they can dial it up (with proper labelling, of course).

Always ask your supplier: What’s your tumbling protocol? It’s a simple question that reveals a lot about their process control and willingness to customize.

See more: Seafood Quality Control Vietnam: Complete Guide to Avoid Oversoaked Products

Checklist for Seafood Buyers Importing Vietnamese Fish Fillets

Ready to order? Not so fast. Here’s your pre-purchase checklist to avoid costly mistakes:

Questions to ask your supplier:

- What is your target moisture content for this product?

- What treatment formulation do you use? (STPP percentage, salt, pH, temperature)

- How long do you tumble the fillets?

- How do you label the product for the EU market?

- Can you provide a Certificate of Analysis (COA) and batch moisture reports?

Documents to review:

- Spec sheet with clear moisture targets and processing methods

- COA with lab-verified moisture, phosphate residue, and microbiological results

- Product label (or mock-up) showing compliance with EU labelling rules

Key risks to watch for:

- Suppliers who can’t (or won’t) explain their moisture control process

- Missing or vague labelling language

- Moisture levels that seem too good to be true (spoiler: they probably are)

If a supplier gets defensive or evasive when you ask these questions, consider it a red flag.

Ensuring Compliance and Quality for the EU Market

At VNSeafoodInsider, we believe that knowledge is your best defense against non-compliance, rejected shipments, and unhappy customers.

Here’s your action plan:

- Ask proactive questions about phosphate treatment in fish fillets, moisture targets, and processing protocols.

- Request full transparency from your supplier—formulas, tumbling times, and labelling practices should all be on the table.

- Stay updated on EU regulations. Rules evolve, and what was compliant last year might not fly today.

- Work with suppliers who understand that “EU treatment standard” isn’t one-size-fits-all—it’s a conversation, not a checkbox.

See more: Top 5 exotic vietnam white fish that the importers should consider

The EU market is demanding, but it’s also lucrative and stable. With the right supplier, clear communication, and a solid understanding of moisture content and phosphate treatment, you can source high-quality fish fillets that meet every regulatory requirement—and exceed your customers’ expectations.

Because at the end of the day, compliance isn’t just about ticking boxes. It’s about building trust, delivering quality, and keeping your supply chain smooth. And that’s something worth investing in.