An importer has just received a shipment of tuna that looked stunning in the photos, but when it arrives, the beautiful red color has turned to an unappetizing brown. Sound familiar? At VNSeafoodInsider, we’ve seen countless importers struggle with this exact scenario. The secret to maintaining that vibrant, market-ready appearance lies in understanding tuna CO treatment and other color preservation methods.

Today, we’ll walk you through the three main approaches that can make or break your tuna import business, and more importantly, which one is right for your target market.

Outline

ToggleWhat is Tuna CO Treatment?

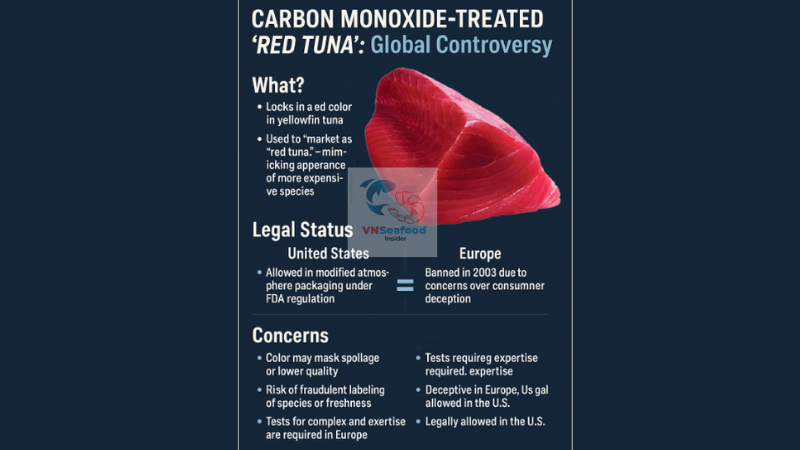

When we talk about modern seafood processing, tuna CO treatment often sparks heated debates in boardrooms worldwide. But let’s cut through the noise and focus on the facts.

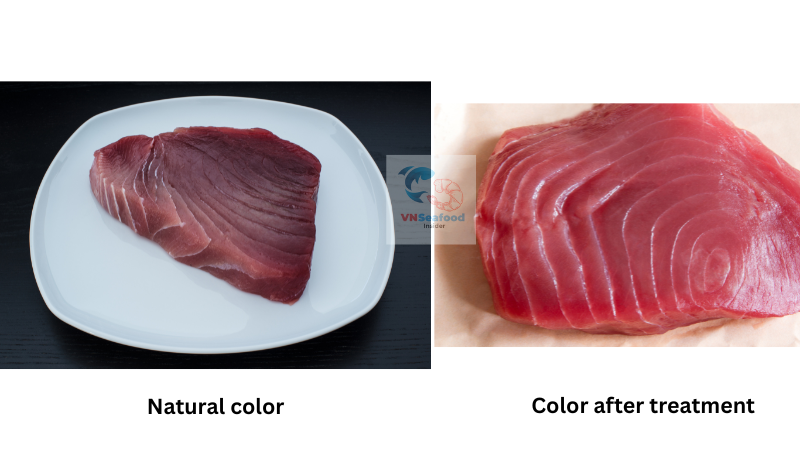

Carbon monoxide treated tuna involves exposing fish to purified CO gas in a controlled environment. Think of it as giving your tuna a protective shield – the CO molecules bind with myoglobin (the protein responsible for that gorgeous red color) and lock it in place. It’s like hitting the pause button on color deterioration.

Here’s the thing that makes this method so popular among processors: it delivers the brightest, most stable red color you’ll find in the market. While other methods might give you a decent appearance for a few days, tuna CO treatment can maintain that fresh-caught look for weeks. The process is highly controlled, using only purified carbon monoxide – not the stuff from car exhausts that people often worry about.

The science behind it is actually quite elegant. When CO binds to myoglobin, it forms carboxymyoglobin, which has an incredibly stable bright red color that resists the oxidation process that normally turns fish brown. For importers dealing with long shipping times and demanding customers, this color stabilization method has become a game-changer.

Natural Tuna Color Preservation Methods

Not everyone’s jumping on the CO bandwagon, though. Many importers and consumers prefer what they consider more traditional approaches to tuna color preservation. Let’s explore these natural alternatives that have been keeping tuna looking fresh for years.

Tasteless Smoke Treatment

Don’t let the name fool you – this isn’t about adding a barbecue flavor to your fish. Tasteless smoke treatment uses filtered wood smoke that’s been stripped of its odor and taste compounds, leaving behind only the color-preserving elements.

The process works by creating a thin protective layer on the fish surface that slows down oxidation. While it doesn’t deliver the same intensity as CO treatment, it offers a middle ground between completely natural methods and chemical treatments. The United States market has embraced this approach, especially among suppliers who want to offer something “more natural” than CO but more effective than purely natural methods.

Vitamin and Antioxidant Treatment

This is where things get interesting for health-conscious markets. Vitamin and antioxidant treatment typically uses vitamin C (ascorbic acid) and other natural antioxidants to fight the oxidation process that causes color loss.

Think of these vitamins as tiny bodyguards protecting your tuna from the elements that want to turn it brown. The process works by neutralizing free radicals – the troublemakers responsible for color deterioration. While this method might not give you the showstopping red color of CO treatment, it’s often preferred by consumers who prioritize natural processing methods.

European and Japanese importers have particularly embraced this approach, viewing it as the perfect balance between effective tuna color preservation and consumer preferences for minimal processing.

See more: MMPA tuna ban 2026

Tuna Import Regulations by Market

Here’s where things get tricky – and why VNSeafoodInsider always emphasizes knowing your target market before choosing a treatment method. Tuna import regulations vary dramatically depending on where you’re shipping.

United States

The U.S. market is relatively relaxed when it comes to tuna CO treatment. The FDA has approved both CO treatment and tasteless smoke methods, recognizing them as safe and effective preservation techniques.

American importers often prefer CO-treated tuna because their consumers prioritize visual appeal and shelf life. The regulatory framework is well-established, making it easier for suppliers to navigate compliance requirements.

European Union

Plot twist: the EU has completely banned carbon monoxide treated tuna. European regulations only allow vitamin and antioxidant treatments, period.

The reasoning? EU regulators worry that CO treatment might mask signs of spoilage, potentially misleading consumers about freshness. This stance has created a clear divide in the global market, forcing suppliers to maintain separate processing lines for European clients.

Japan

Japanese tuna import regulations take a middle-ground approach. While they don’t officially approve CO treatment, the focus is more on meeting strict quality standards regardless of the preservation method used.

Most Japanese importers prefer vitamin-treated tuna, aligning with their cultural emphasis on natural processing and ingredient purity. The market demands are incredibly specific, often requiring detailed documentation about processing methods.

See more: How to Negotiate Prices for Tuna Import from Vietnam

Safety Comparison: CO Treatment vs Natural Methods

Let’s address the elephant in the room – safety concerns about carbon monoxide treated tuna.

Here’s the reality: when processed according to established food safety standards, all three methods are completely safe for consumption. The key phrase here is “properly processed.” Tuna CO treatment uses purified CO gas in controlled environments, nothing like the dangerous carbon monoxide from incomplete combustion.

Food safety protocols for all methods include temperature control, proper handling procedures, and regular quality testing. The difference lies not in safety but in regulatory approval and consumer perception. At VNSeafoodInsider, we’ve seen extensive testing data showing that properly processed CO-treated tuna meets all international safety standards.

Choosing the Right Treatment for Your Market

So how do you decide? It’s not rocket science, but it does require some homework.

First, check your target market’s regulations – this isn’t negotiable. EU-bound shipments must use vitamin treatment, while U.S. importers can choose from all three options.

Second, consider your customers’ preferences and price points. Tuna CO treatment typically costs more but delivers superior visual results. Natural methods might have lower processing costs but could result in shorter shelf life.

Finally, factor in your logistics. Longer shipping times might favor CO treatment, while shorter supply chains could work fine with vitamin-treated fish.

See more: Top 5 exotic vietnam white fish that the importers should consider

Conclusion for Tuna CO Treatment

There’s no universal “best” method for tuna color preservation – it all comes down to understanding your market and matching your processing choice accordingly. Whether you choose tuna CO treatment for its superior color stability or prefer natural vitamin methods for regulatory compliance, the key is working with suppliers who understand these nuances.

At VNSeafoodInsider, we recommend consulting with experienced Vietnamese seafood suppliers who can guide you through the maze of tuna import regulations and help you choose the treatment method that best serves your specific market needs. After all, the right choice today shapes your success tomorrow.